Views: 14 Author: Site Editor Publish Time: 2022-05-17 Origin: Site

In the process of oil production by pumping unit, high-pressure gas flow will appear suddenly in the well, If the wellhead is not equipped with a blowout preventer, the stuffing box alone is not enough to control the wellhead pressure and can easily cause a blowout. Therefore, it is necessary to install sucker rod blowout preventer at the wellhead.

The sucker rod blowout preventer developed and produced by our company with small size, occupies little space of wellhead, and is easy to operate. It is produced according to API 16A standard, and its sealing performance is safe and reliable.

Product Specifications and Models:

Model | For Polished rod | Upper thread | Lower thread | Rated pressure |

CFQ2000 | 1-1/8, 1-1/4, 1-1/2 | 2-7/8, 3-1/2 Box | 2-7/8, 3-1/2 Pin | 2000 PSI |

CFQ3000 | 1-1/8, 1-1/4, 1-1/2 | 2-7/8, 3-1/2 Box | 2-7/8, 3-1/2 Pin | 3000 PSI |

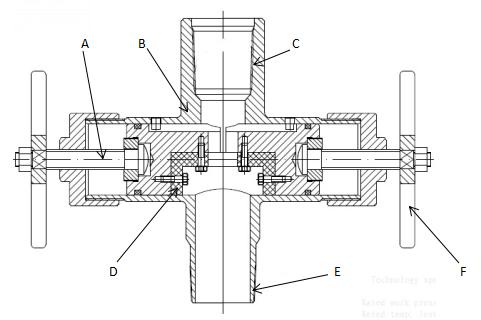

Product structure:

This product is mainly composed of shell, leading screw, upper thread, lower thread, hand wheel and sealing ram.

A: Leading screw B: Shell C: Upper thread D: Sealing ram E: Lower thread F: Hand wheel

Installation operation

1. Installation

Before installing the blowout preventer, check whether the locking nuts at both ends are locked, whether the lead screw rotates flexibly, and whether the sealing ram are damaged. Connect the lower connector to the wellhead, making sure the threads are tight. Connect the sucker rod and stuffing box to the upper connector of blowout preventer, making sure the threads are tight.

2. Operation during normal oil production

During oil production, the sealing ram of the blowout preventer should be in the fully open position. The operation method is to turn the leading screw counterclockwise to open the sealing ram to fully open state. When the sucker rod is operating during oil extraction, neither the rod body nor the coupling can collide with the sealing ram.

3. Blowout preventer close operation

When a blowout or kick accident occurs downhole, the oil production operation should be stopped immediately and the blowout preventer should be closed immediately. The operation method is to rotate the hand wheels at both ends clockwise at the same time until the ram holds the sucker rod tightly and seals the liquid in the well. When closing, the hand wheels at both ends should be rotated at the same time, not only one end or one end is rotated too much, and the other end is rotated too little.

Transport and storage

1. Moisture-proof protection should be done during transportation to avoid bumps.

2. Warehouse storage should be placed on shelves, protected from moisture, light, and avoid contact with corrosive substances.

3. The rubber in the blowout preventer is naturally aging. If the blowout preventer has not been used for a long time, check whether the rubber is aging. Blowout preventer seals that are in long service should also be replaced periodically to ensure they are always in good condition.

TEL: +86-022-63962564